Cardamom processing

Practical Action

Cleaning

The crop should be cleaned before processing. The first stage is to remove dust and dirt using a

winnowing basket. This can be made locally from bamboo, palm or other leaves. A worker who is

used to doing this can clean up to 100kg of cardamom in an eight hour day. Small machines

are available for cleaning, but they are often not cost effective.

After winnowing the capsules are washed in clean water. Two or three large plastic buckets (15

litre capacity) are sufficient for small amounts but for large quantities, it may be better to use a

sink with a drainage hole. Only water that is safe to drink should be used. It should be changed

regularly to prevent contamination.

Pre-treatment

After washing, the stalks are removed from the cardamom capsules by hand.

The capsules can be soaked in a solution of sodium bicarbonate (2-5%) for ten minutes to help

retain the green colour. This is an optional step. A 2% solution of sodium bicarbonate is

prepared by dissolving 20g (about 4 tea spoons) of sodium bicarbonate in 1 litre of water.

Drying

This is the most important part of the process as it affects the quality of the final product. It is

important to dry the cardamom capsules as soon after harvest as possible to prevent the loss of

flavour. It is also important that the drying process is as short as possible so that mould does

not grow on the capsules and the bright green colour is retained. The drying temperature should

not be above 50°C as this affects the colour and delicate flavour of the final product. In most

places, cardamom capsules with a good green colour can be sold for a premium price.

The moisture content of a fresh cardamom capsule is about 85%. This needs to be reduced to

10% in the dried product so the cardamom capsules can be stored. If the drying period is too

long mould can start to grow on the cardamom. There are several options available to the small-

scale processor, depending upon the size of the business and the local weather conditions at the

time of processing. Each method has different advantages and disadvantages:

Sun drying. Traditionally, cardamom capsules are spread on a concrete floor to dry using the

natural heat from the sun. The capsules should be placed away from direct sunlight to preserve

the green colour (strong sunlight will make the colour fade). This is the simplest and cheapest

method, but does not produce the highest quality product. It is only successful in places where

the climate is dry and hot. During the monsoon season for example, drying will be interrupted by

rainfall which can cause mould to grow on the capsules. During drying, the capsules may be

contaminated by dirt and dust from their surroundings.

Solar drying. The use of a solar dryer should improve the quality of the dried capsules as it is a

cleaner, more controlled environment. However, it is not a popular choice as the green colour is

lost during drying. The solar dryer is really only useful in dry hot sunny climates. The capsules

should be placed in the dryer, out of direct sunlight, and dried until they have a final moisture

content of 10%. In places with high humidity the solar dryer can only be used together with an

extractor fan to remove the humid air.

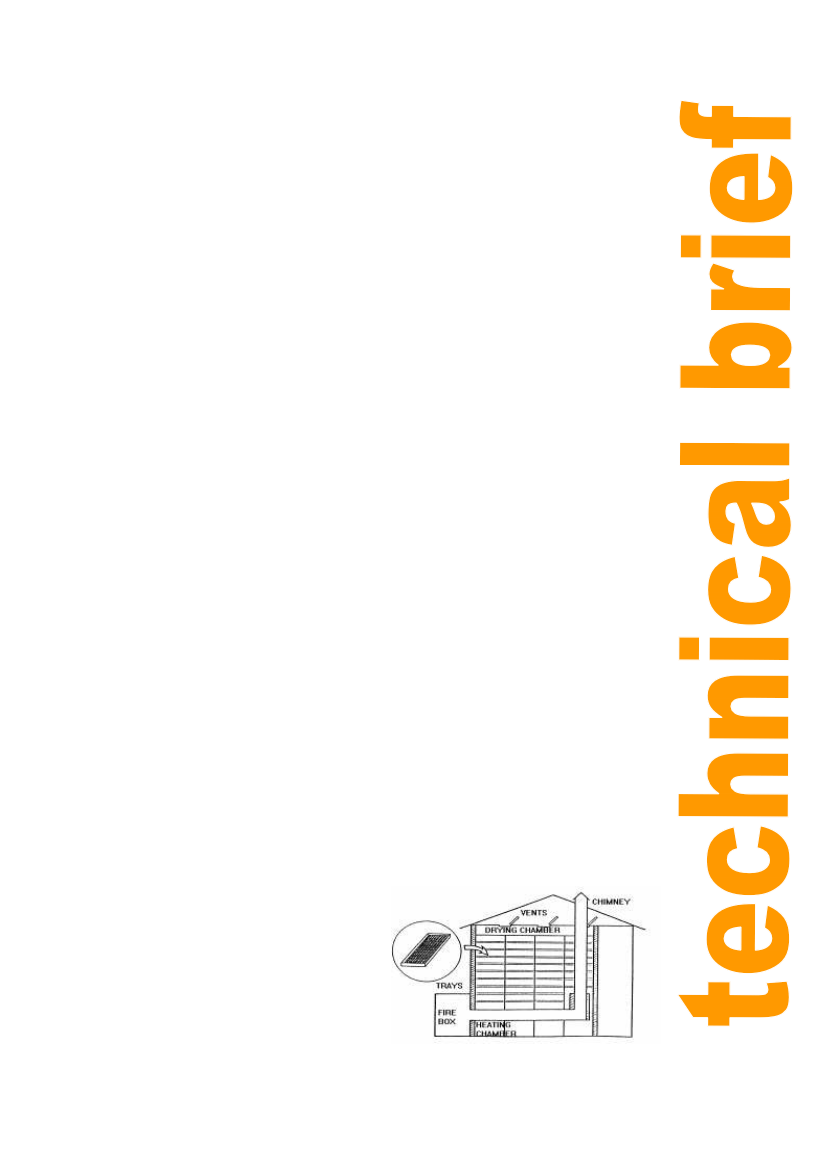

Wood-fired dryer. In India, cardamom

capsules are traditionally dried in curing

houses, using wood to provide the heat. This

method puts a huge demand on firewood.

The smoke from the fire can give the

capsules an unpleasant smoked flavour. The

processor must ensure that the capsules

closest to the heat source are not burnt or

scorched. Cardamom capsules dried by this

method are not of the highest quality.

Figure 2: A typical tray dryer

2